FAQ

Documentation and forms

Competency and qualification requirements

Certification rules

Additional capabilities

Appeals and complaints

Accreditation

Contact information

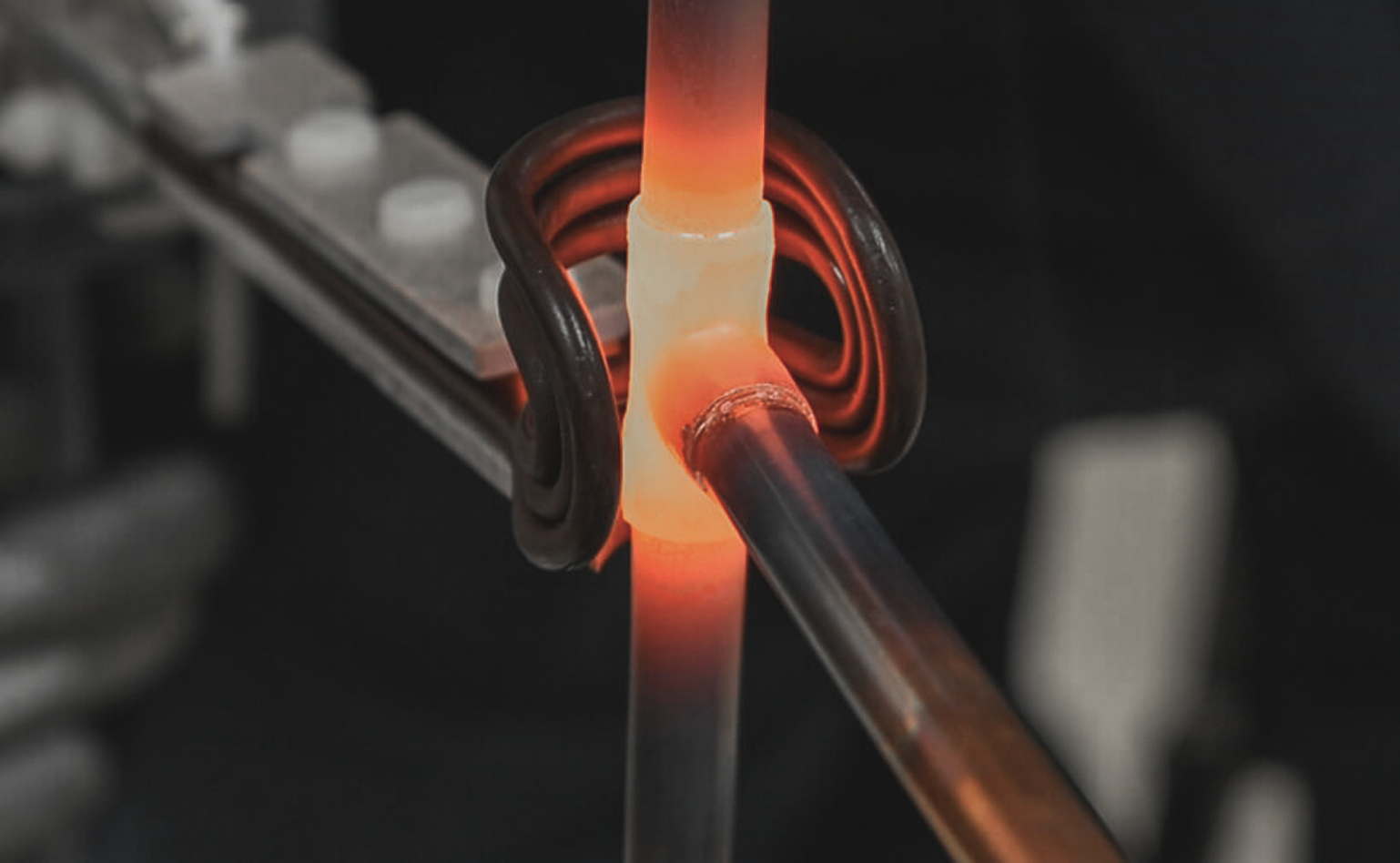

Certification of personnel for performing permanent joints in the field of brazing is crucial for ensuring the safety and quality of connections in a variety of industrial applications, with particular emphasis on pressure equipment and assemblies. The brazing process requires not only precise technical skills but also knowledge of the relevant standards and procedures that guarantee the durability and reliability of the joints.

The Central Refrigeration Centre "COCH" provides the opportunity to obtain a certificate confirming the competence of a brazer in two areas:

- In the legally regulated area – Approval of personnel for performing permanent joints in accordance with the provisions of EU legislation - the Pressure Equipment Directive (PED) 2014/68/EU and the requirements of the PN-EN ISO 13585 standard.

- In the voluntary area – Certification in accordance with the requirements of the PN-EN ISO 13585 standard.

| Certification Required by Law | Voluntary Certification |

|---|---|

|

Certification required by law in accordance with the Pressure Equipment Directive (PED) 2014/68/EU and based on the requirements of the PN-EN ISO 13585 standard is carried out by the European Notified Body No. 1462 (COCH), which:

|

Voluntary certification of the competence of brazers and brazing operators is carried out by the COCH Personnel Certification Body in accordance with the PN-EN ISO 13585 standard. Voluntary certification may be applied for by:

|

The requirements for the qualification of brazers and brazing operators for metals are specified in the standard PN-EN ISO 13585 "Brazing — Qualification of brazers and brazing operators".

The current edition of the standard PN-EN ISO 13585:2025-01 (EN ISO 13585:2024) has replaced the standard PN-EN ISO 13585:2012 (EN ISO 13585:2012).

What does a brazers do and what requirements must he meet?

Brazer’s Role:

The brazer, responsible for making permanent joints, must possess special qualifications and skills. Knowledge of various brazing techniques and the properties of the materials from which the joined elements are made is crucial. In addition to the precise execution of the brazing process, the brazer is responsible for preparing the joining surfaces, including cleaning and accurate fitting of the components. Controlling the brazing parameters is essential to ensure the durability and safety of the joint.

Requirements and Certification:

The requirements for a brazer’s qualifications are particularly important for applications in pressure equipment, where joints must meet strict safety and durability standards. Therefore, the certification process for brazers in accordance with the PN-EN ISO 13585 standard is essential. It ensures that the personnel performing the brazing are properly trained and competent to work according to the highest quality and safety standards.

What is the difference between legally required certification and voluntary certification?

Legally required certification under the PED 2014/68/EU directive covers the entities specified therein, e.g., manufacturers of pressure equipment, assemblies, and installations classified in the relevant categories.

The PED directive was implemented into Polish law through the “Regulation of the Minister of Development of 11 July 2016 on the requirements for pressure equipment and pressure equipment assemblies.”

In accordance with the requirements of the PED 2014/68/EU directive (Annex I, point 3.1.2 – Permanent joining): For pressure equipment in categories II, III, and IV, the operating procedures and personnel must be approved by a competent third party chosen by the manufacturer, which may be:

- a notified body;

- a third-party organization recognized by a Member State in accordance with Article 20 of the directive;

NOTE: In addition to the certification of the brazer / brazing operator, it may also be necessary to approve the operating procedures (qualification of brazing technology). Check the details: https://www.coch.pl/zatwierdzanie-procedur-operacyjnych-polaczen-nierozlacznych-ped-2014-68-ue/

Voluntary certification can be carried out for both entities and individuals. It confirms the competence of the brazer in accordance with international standards (PN-EN ISO 13585) by an independent third party.

How to check the pressure category of equipment, assemblies, and installations?

What regulations govern the certification of solderer competency?

Regulations Governing Brazer Certification

Our accredited certification program, developed according to best practices, adheres to specific regulations outlined in several documents and standards. These include:

PN-EN ISO 13585 – This standard pertains to hard brazing, detailing the qualification of brazers and operators involved in hard soldering processes. It defines the requirements for knowledge, skills, and experience necessary to effectively and safely perform hard brazing operations.

PN-EN 12799:2003 – This standard covers general principles of brazing technique, along with requirements for materials, tools, and techniques used during brazing. It provides fundamental guidelines for safety and quality in brazered joints.

PN-EN ISO/IEC 17024 – This standard outlines general requirements for bodies certifying individuals. It establishes accreditation criteria for certifying bodies, ensuring that the certification process is conducted in accordance with the highest standards of quality and objectivity.

Additionally, Centralny Ośrodek Chłodnictwa “COCH” in Kraków has extensive experience in training and certification, integral to our certification program. COCH provides high-quality training and professional certification, fully tailored to the needs and requirements of the brazing industry.

Through adherence to these standards and leveraging COCH’s experience, we ensure that our certified brazers possess not only the necessary theoretical knowledge but also practical skills to perform effective and safe hard brazing, meeting the highest standards of quality and safety.

What does the certification procedure cover?

Our Brazer Certification Program PR-04.2

Our brazer certification program PR-04.2, based on the PN-EN ISO 13585 “Brazing — Qualification of brazers and brazing operators” standard, includes the following stages:

-

Verification of Qualifications and Experience (assessment of the submitted application):

Candidates must meet the requirements for education and experience in the field of brazing, especially in the brazing of steel, copper, and their alloys.

-

Theoretical Examination:

A written exam tests the candidates’ knowledge of the requirements of the PN-EN ISO 13585 standard and methods for brazing steel and copper (methods designated as 912 according to PN-EN ISO 4063).

-

Practical Examination:

Candidates perform a practical exam that assesses their skills in the practical application of brazing techniques in accordance with the standard.

-

Assessment and Certification:

After successfully passing both exams, candidates receive a certificate confirming their competence in brazing in accordance with the PN-EN ISO 13585 standard.

Through this process, we ensure that certified brazers have the appropriate qualifications and skills to perform brazing in a manner consistent with international quality and safety standards.

What documents must be submitted with the certification application?

The following must be attached to the certification application:

- Documents confirming the completion of theoretical and practical training in making permanent joints (appropriate for the requested certification).

- A current medical certificate stating no contraindications to performing work within the requested scope and, if applicable, information about the need for the certifying body to adapt to the special needs of the applicant during the certification process.

- A pBPS / BPS instruction, appropriate for the requested scope of qualification, prepared and approved by the Manufacturer (in the case of personnel approval in accordance with PED 2014/68/EU) or the Employer/Applicant (in the case of voluntary certification), along with the maximum time for making the joint under production conditions (if specified).

Detailed information about the certification process

Competency and qualification requirements

Here are the competency and qualification requirements for individuals applying for certification in performing non-destructive connections, according to our certification program:

- Physical Aptitude: Candidates should possess specific physical attributes including good vision, color recognition, tactile sensitivity, fine eye-hand coordination, and physical dexterity. These characteristics are essential for performing tasks related to non-destructive connection processes, depending on the brazing method.

- Age Requirements: Candidates must be at least 18 years old.

- Training in Non-Destructive Connections: Applicants must provide a certificate of completion from an appropriate training program in non-destructive connections that aligns with the desired certification. An exception applies for recertification situations.

- Medical Certificate: Candidates must present a current medical certificate confirming their fitness for performing tasks within the scope of the applied certification, specifically for non-destructive connection tasks.

Ensuring compliance with these requirements is crucial to maintaining safety, effectiveness, and quality in the soldering process, as well as meeting certification standards.

Certification rules

The certification rules for personnel performing non-destructive connections, as detailed in our certification program, encompass the following stages:

Application Submission: The candidate submits an application for certification to the Personnel Certification Body.

Registration and Application Evaluation: The candidate’s application is registered and undergoes a thorough evaluation for completeness and compliance with requirements.

Knowledge Assessment (Theoretical Exam) and Practical Skills Assessment (Practical Exam): The candidate undergoes a theoretical exam to assess their theoretical knowledge related to non-destructive connection processes. Additionally, they undergo a practical exam where they demonstrate their practical skills.

Performance of Tests and Laboratory Examinations: In some cases, specialized tests and laboratory examinations may be required to confirm the candidate’s ability to perform non-destructive connections.

Certification Decision: Based on the assessment results of the application, exams, and any necessary tests, a decision is made regarding certification.

Issuance of Certificate: Upon a positive decision, the candidate is issued a certificate confirming their qualifications to perform non-destructive connections in accordance with specified requirements.

Supervision of Certificate Holder: The certifying body oversees the certificate holder, monitoring their activities to ensure they maintain the required standards.

Recertification: The certificate has a specified validity period. Upon expiration, the certificate holder may apply for recertification, which involves meeting specific conditions and possibly undergoing additional tests or training.

These stages ensure a comprehensive approach to certification aimed at ensuring high quality and safety in the performance of non-destructive connections, in compliance with the requirements of Directive 2014/68/EU (PED).

Appeals and Complaints

Information on the procedure for handling complaints and appeals can be found at this link.

Additional capabilities

Soldering in refrigeration method 912 - training course

Go to the training page

Certification of refrigeration competence

See what certification opportunities you have in the refrigeration area

Why Choose COCH Certification?

We invite you to discover the world of brazing - a key process in the industry that provides permanent and irreversible connections of structural components and technological installations.

Accreditation

Quality accreditation - a guarantee of trust

The Certification Department is accredited AC 036 and AC 056 by the Polish Accreditation Center and specializes in the certification of refrigeration destination products and personnel competence in the field of refrigeration.

Our team consists of qualified and experienced specialists who offer comprehensive assistance in the certification preparation and certification process, supervision and personnel competence development. With our services, we provide customers with reliable and professional service at every stage of cooperation.